Publiée le 29.08.23

Focus recrute au bureau d’études

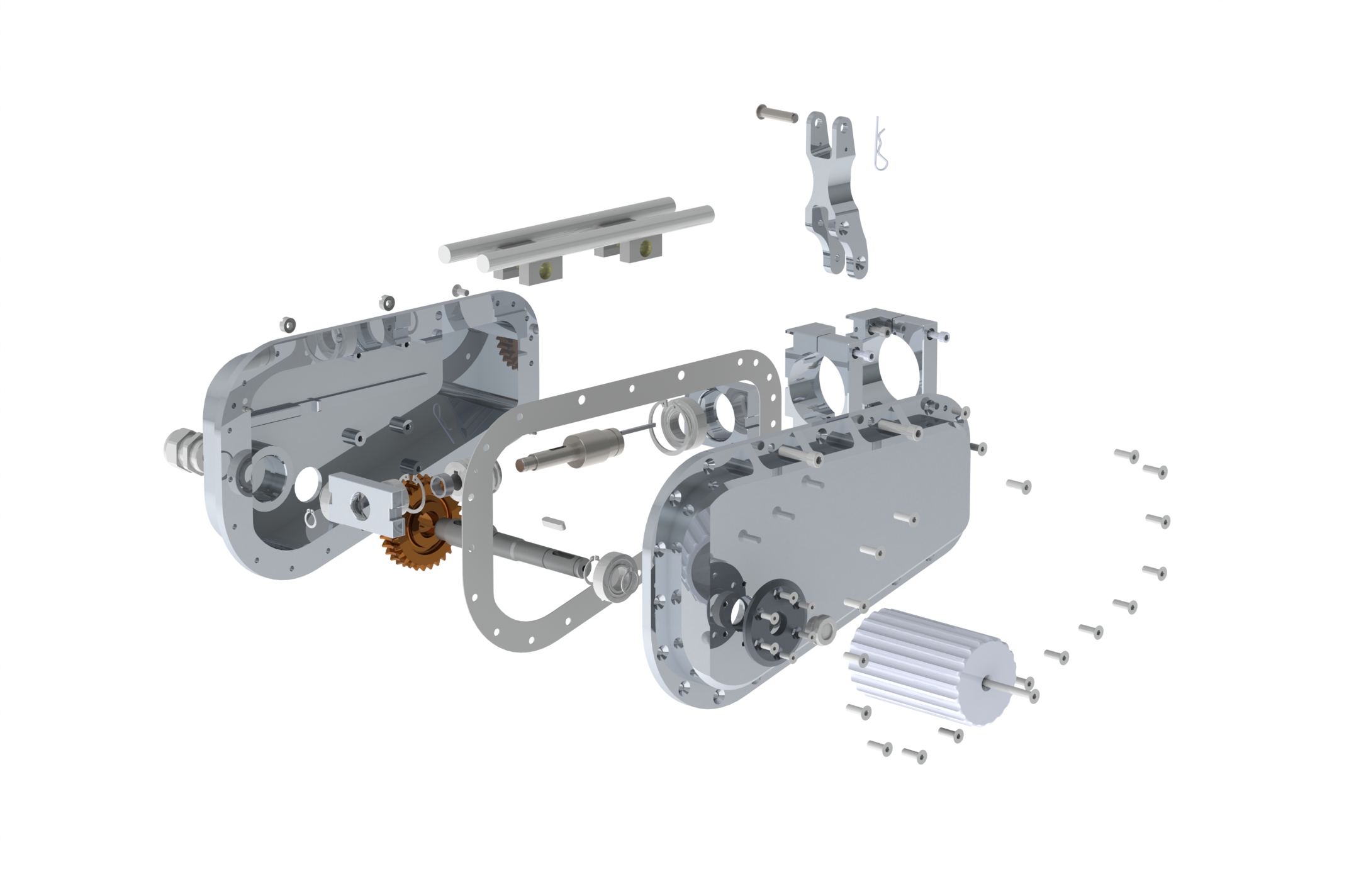

Nous recherchons un dessinateur, concepteur de machines spéciales pour venir étoffer notre équipe au bureau d’études !

Si cela vous intéresse, envoyez-nous un mail à l’adresse suivante : contact@focus-indsutrie.fr

En savoir plus